Volkswagen (China) Technology Co., Ltd. (VCTC) officially inaugurated its new batch of test workshops in Hefei, Anhui province, on November 25, 2025. This marks it as Volkswagen Group’s first comprehensive R&D base outside its German headquarters with full-process R&D and validation capabilities, and its largest comprehensive R&D centre globally outside Germany.

The new workshops signify the establishment of a complete end-to-end R&D system for Volkswagen Group in China, integrating software development, hardware testing, and vehicle validation across the entire chain. This is the first time the Group has achieved full-process R&D, compliance approval, and mass production capabilities for new vehicle platforms and key technologies outside Germany, enabling simultaneous development and validation from the early stages of R&D.

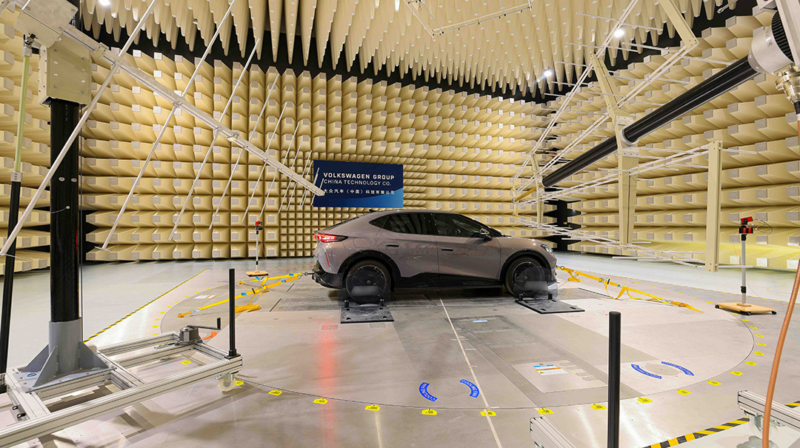

According to Volkswagen Group China, the test workshops span approximately 100,000 square meters and are equipped with over a hundred advanced laboratories. These facilities cover critical areas such as software and hardware integration, battery and powertrain testing, and vehicle-level validation, forming a complete end-to-end R&D closed loop. This setup is expected to directly reduce overall vehicle development time by 30%.

Oliver Blume, Chairman of the Board of Management of Volkswagen Group, emphasised the accelerating “In China, for China” strategy. “At our R&D centre in Hefei, China, we have fully established a comprehensive system to support the R&D, testing, and localised production of new-generation intelligent connected vehicles,” Blume stated. “This milestone will ensure our local R&D speed becomes more agile, market response more efficient, and more deeply aligned with the core demands of Chinese consumers.”

Ralf Brandstätter, Member of the Board of Management of Volkswagen Group for China and Chairman and CEO of Volkswagen Group China, highlighted the competitive nature of the Chinese market. “China is the most competitive automotive market globally, and local customers have extremely high demands for innovation speed and quality. This is precisely why we continue to strengthen our ‘In China, for China’ R&D capabilities,” Brandstätter said. “By expanding our R&D footprint in Hefei, we are steadily enhancing our localised technology development capabilities to respond faster to Chinese consumer needs.”

VCTC, which officially commenced operations in January 2024, is a core pillar of Volkswagen Group’s “In China, for China” strategy. It is the Group’s largest comprehensive R&D centre outside Germany, and its only innovation engine focused solely on electrification and intelligent connected vehicles. VCTC integrates core R&D modules and decision-making processes for local vehicle and technology projects, collaborating closely with joint venture R&D teams.

A key focus at VCTC’s software and hardware test workshops in Hefei is the development of the Group’s first Central Computing and Regional Control Electronic/Electrical Architecture (CEA) for the Chinese market. This first generation of CEA is being advanced with an 18-month development cycle. Leveraging new Software Defined Vehicle (SDV) development processes, overall vehicle development time is projected to be reduced by approximately 30%.

Furthermore, localised independent development and supplier collaboration during the concept R&D phase for models and technologies could lead to new vehicle cost reductions of up to 50% for some key projects. The CEA architecture will also ensure smooth and reliable software and hardware integration for intelligent cockpit functions, Advanced Driver-Assistance Systems (ADAS), and provide vehicle-level OTA update capabilities for new-generation models.

These facilities enable more comprehensive validation of core vehicle systems at an earlier stage, supporting not only the Chinese market but also products and technologies exported to overseas markets such as ASEAN and the Middle East.

Within the battery and powertrain integration test centre, VCTC engineers can test up to 500 battery systems annually, covering performance, lifespan, safety, and environmental adaptability, extending to electric drive systems, thermal management systems, and battery cells. The platform and module test centre features advanced facilities like an Electromagnetic Compatibility (EMC) laboratory to ensure the reliability of vehicle electronics and a vehicle durability test bench that can simulate various global road conditions indoors. Combined with the city test track also located at VCTC, Volkswagen Group has established a complete closed loop from design and development to testing and validation in Hefei, closely collaborating with its global R&D network.

Volkswagen Group plans to further expand VCTC’s R&D capabilities. A Functional Integration Test (FIT) laboratory, one of only two such facilities globally capable of simulating complex extreme environments, is slated to become operational in the new workshops by mid-2026.