Solid-state battery: 100 kg pack to exceed 1,000 km range, Chinese scientists overcome bottleneck

Chinese research teams have achieved significant progress in addressing one of the main technical bottlenecks in all-solid-state lithium-metal batteries, according to a report by China Central Television (CCTV), the country’s state-run national broadcaster, on October 16. The development could potentially allow a 100-kg battery pack to deliver driving ranges exceeding 1,000 km, compared to roughly 500 km previously.

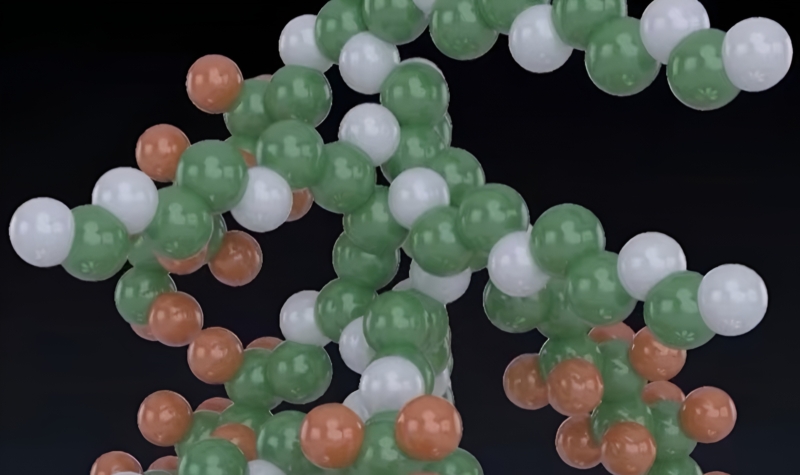

Conventional sulfide-based solid electrolytes are extremely hard and brittle, similar to ceramics, while lithium-metal anodes are soft and pliable. When combined, the uneven interface between these two materials impedes ion transport, reducing the efficiency of charging and discharging.

To overcome this issue, several research groups across China have developed different approaches aimed at improving the solid–solid interface between the electrode and electrolyte. Three primary methods were highlighted in the CCTV report.

The first comes from the Institute of Physics at the Chinese Academy of Sciences, which introduced iodine ions as an interfacial “mediator.” During battery operation, these ions migrate to the interface between the electrode and electrolyte, where they help attract lithium ions and fill microscopic gaps. This self-adjusting mechanism allows closer contact between materials, addressing one of the key challenges to practical solid-state batteries.

The second method, developed by the Institute of Metal Research under the Chinese Academy of Sciences, focuses on mechanical flexibility. Researchers created a polymer-based framework for the electrolyte, improving its ability to resist bending and twisting while maintaining structural integrity. Tests reportedly showed that the modified material could withstand 20,000 bending cycles and twisting without damage. Additional chemical components within the structure also enhanced lithium-ion mobility and increased the material’s energy storage capacity by up to 86%.

The third approach, from Tsinghua University, involves using fluorinated polyether materials to reinforce the electrolyte. Fluorine’s strong resistance to high voltage helps form a stable fluoride layer on the electrode surface, preventing electrical breakdown under stress. The modified cells reportedly passed puncture tests and 120°C thermal tests without explosion, showing improved safety and stability at high charge levels.

Together, these advances suggest that solid-state lithium-metal batteries in China are approaching a stage where both energy density and safety could be significantly improved. However, further testing and industrial validation will be required before commercial applications.