Xpeng launches world’s first mass-production modular flying car line rollout

Xpeng Motors’ subsidiary Aridge has rolled out the first “Land Carrier” modular flying car from its Guangzhou facility in Huangpu District, marking the launch of what the company calls the world’s first mass-production line for flying cars. The initial aircraft will be used for experimental test flights to verify performance and manufacturing processes, forming the basis for full-scale deliveries expected next year.

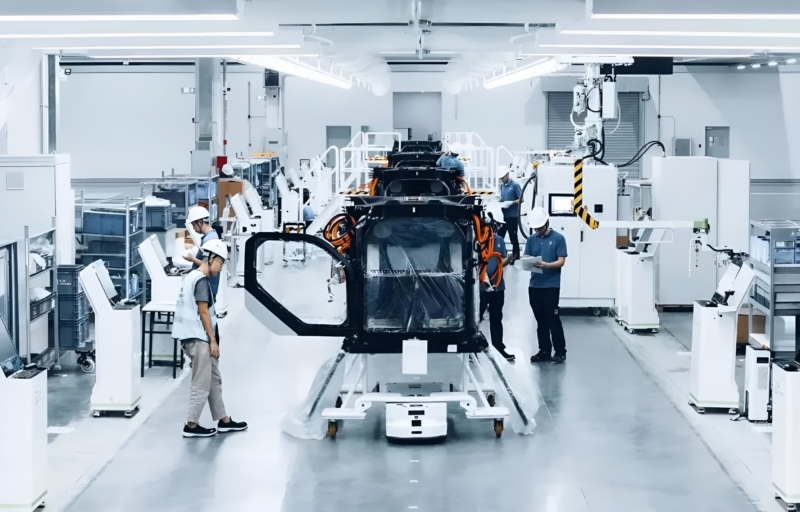

The factory spans roughly 120,000 square meters and is designed to produce Xpeng’s modular flying car, which separates into a land vehicle and an aerial vehicle. The land module, also known as the “mother vehicle,” features a three-axle, six-wheel configuration with all-wheel drive and rear-wheel steering, providing both load capacity and off-road capability.

Measuring approximately 5.5 meters long, 2 meters wide, and 2 meters high, it fits into standard parking spaces and can be driven with a conventional driver’s license. The aerial module is an electric, six-rotor, dual-ducted design featuring a carbon-fibre fuselage and rotor blades, which balance strength and weight. A 270-degree panoramic cockpit offers an expansive view for flight.

The facility includes five core workshops: composites, propulsion, assembly, painting, and final integration. The composites workshop produces carbon-fibre components, including arms, rotor blades, and floor panels, with an annual target of 300 tons, making it one of the most extensive aviation carbon-fibre component facilities worldwide. The propulsion workshop assembles and tests lift and flight-control units using the world’s first integrated assembly and testing line for electric drives and rotors, with automated traceability for all components.

Fuselage components are joined in the assembly workshop using cold-connection techniques, including riveting and adhesive bonding. The painting workshop employs an “8C6B” multi-layer spraying process on a flexible high-automation line. In contrast, the final assembly workshop integrates nine major systems and conducts testing to meet design and airworthiness standards. A cloud-based calibration system automatically tests autonomous driving, flight control, and centre-of-gravity measurements.

The “Land Carrier” supports both manual and autonomous flight modes. Manual control utilises a single-stick system for one-handed operation. At the same time, autonomous mode offers intelligent route planning, automated flight along preset paths, one-button takeoff and return, 3D composite vision, and landing assistance.

The factory adheres to a “refined, intelligent, green” principle, utilising photovoltaic power, energy-efficient equipment, and a digital energy management system to minimise carbon emissions. At full capacity, the plant is designed to produce 10,000 units annually, with an initial capacity of 5,000, rolling out one aircraft every 30 minutes.