BYD Yangwang details 3D-printed body tech behind U9 Xtreme, globe’s fastest production ride

BYD’s premium performance brand, Yangwang, has released new technical details about the 3D-printed body structure used in the U9 Xtreme (U9X), shortly after the model set an official Nürburgring Nordschleife lap record for production electric cars, as reported by IT-Home. The U9X achieved a certified time of 6:59.157, making it the first mass-produced EV to complete a sub-seven-minute lap on the circuit.

According to Yang Feng, head of the Yangwang Research Institute at BYD Auto Engineering Research Institute, the 3D printing project represents an experimental step toward new vehicle manufacturing paradigms. He shared the technology’s development history, which integrates aerospace-grade materials and processes to balance rigidity, safety, and weight reduction.

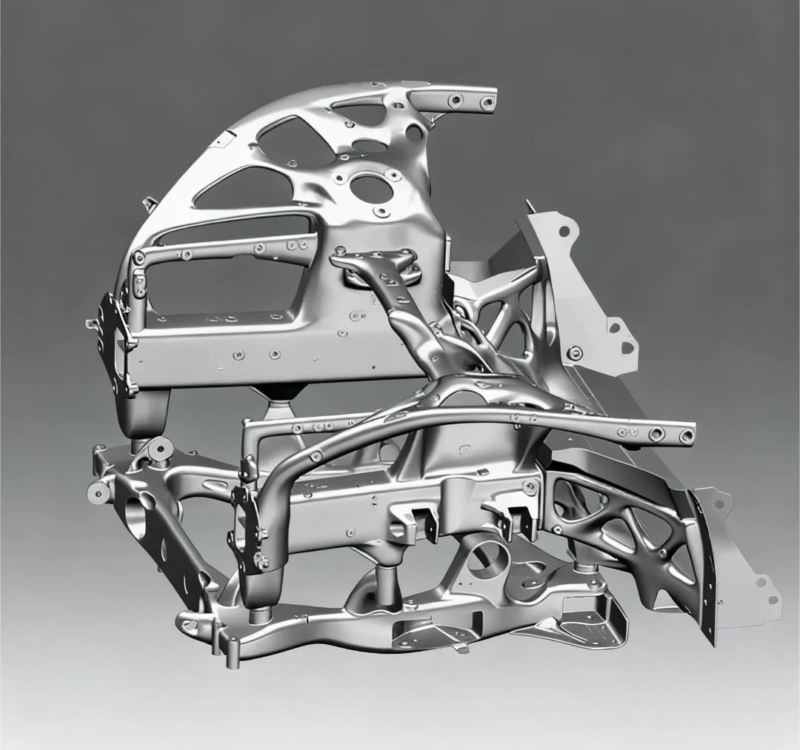

Yang said the engineering team used high-strength aluminium alloy explicitly developed for the project. The material, derived from aerospace lightweighting research, is said to offer three times the yield strength of conventional cast aluminium while maintaining structural balance.

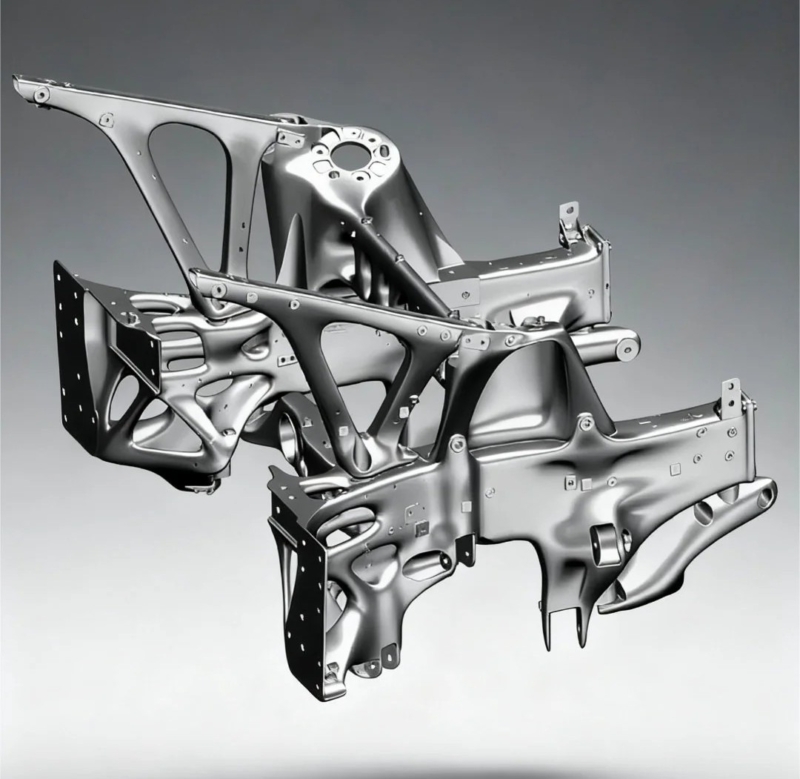

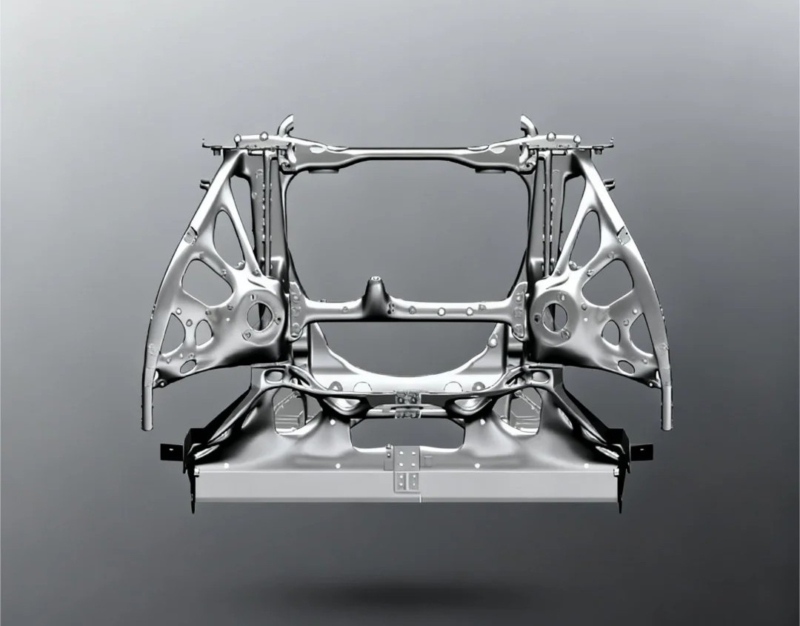

The team also introduced what it calls multidimensional surface parametric modelling, designed to address challenges in continuous transitions across complex curved surfaces. This led to the creation of the Printing HyperCell structure, a global first in automotive use, which integrates internal cavities and ribs in a honeycomb-like design. The new structure reportedly increases torsional stiffness by more than 200% compared to solid equivalents of the same weight.

Manufacturing relies on laser selective melting, achieving a precision of up to 0.03 mm. To handle thermal deformation in significant thin-wall components, the team implemented dynamic process compensation algorithms, ensuring tolerance accuracy within 0.1 mm on key installation surfaces—comparable to standards used in aircraft engine components.

This combination of materials, topology optimisation, and manufacturing precision allows the 3D-printed body to maintain stability and dynamic performance even at 400 km/h. The approach also enables tighter integration between vehicle subsystems, improving overall handling characteristics.

The U9X’s 3D-printed body recently won an award at the European Car Body Conference, making it the only Chinese-brand project recognised at the event. The award, based on the highest jury score, highlights the successful adaptation of aerospace-grade engineering to automotive applications and suggests potential future paths for cross-industry manufacturing innovation.