Chinese state-owned automaker Dongfeng postponed mass production of solid-state batteries to 2027, CarNewsChina discovered from the company’s latest release. At the moment, Dongfeng actively explores this technology, applying it to test cars.

In November 2025, Dongfeng Automobile shared that it will commence the mass-production of solid-state batteries with an energy density of 350 Wh/kg in September 2026. The company had already established a 0.2 GWh pilot production line.

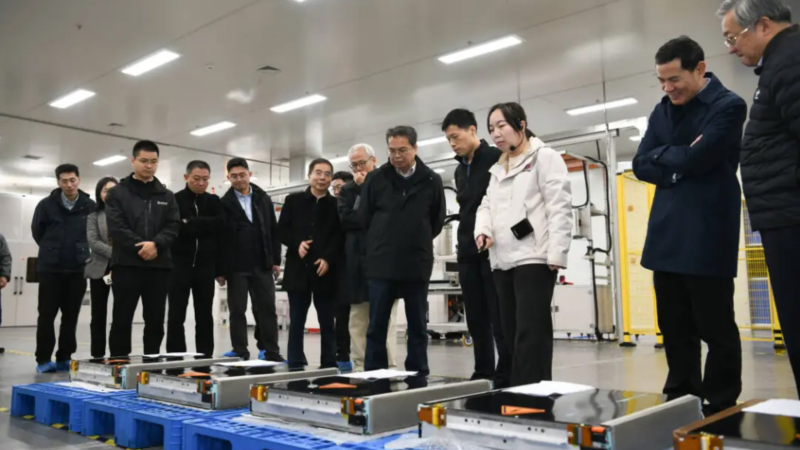

However, the mentioned road map was adjusted during the official visit of the Dongfeng Motor Corporation delegation of external directors at the solid-state battery plant. They conducted on-site inspections of the solid-state battery cell and module production lines.

It was disclosed that Dongfeng successfully developed liquid-solid-state batteries with new electrolyte membrane composite technology and electrode solidification. This tech increases the electric range of new energy vehicles. The R&D team announced it aims to launch the all-solid-state battery deployment in 2027. So, the launch of this technology was moved from September 2026 to 2027.

The company hinted at reasons for this postponement. Currently, the R&D team is engaged in in-depth discussion on key issues such as technical routes, cost control, and industrialization pace. However, the company shared a photo of the Dongfeng eπ 007 sedan with a solid-state battery on board. Members of the delegation of the company’s external directors have driven this car on site.

More about the Dongfeng solid-state battery

As mentioned, the Dongfeng’s solid-state battery has an energy density of 350 Wh/kg. It employs a multi-component system with a ternary cathode, a silicon-carbon anode, and an oxide polymer composite solid electrolyte. The battery retains 72% of its energy at -30°C. It also surpassed thermal-chamber safety tests at 170°C.

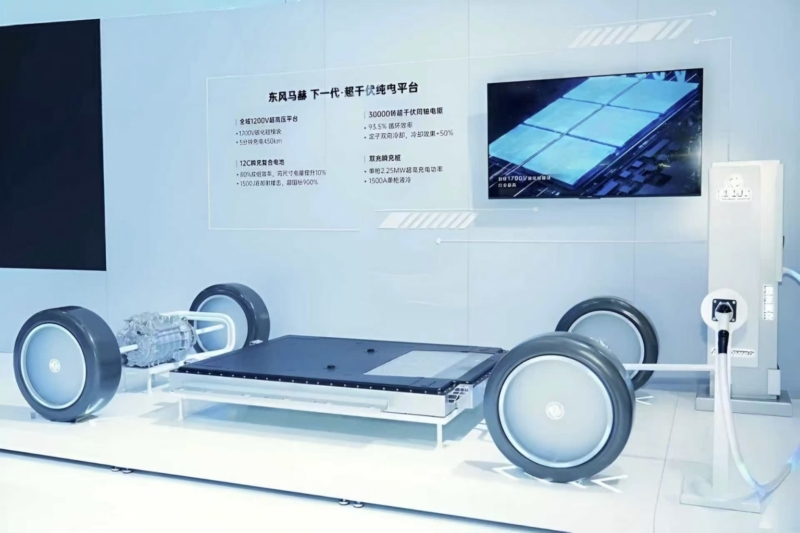

The solid-state battery will become a part of Dongfeng’s Mach Super-kV Pure-Electric Platform. It adopts a 1,200 V high-voltage architecture with a 1,700 V SiC power module. It boasts a 2 MW single-connector charging. An EV on this architecture can charge 2.5 km of range in 1 second. The platform also features an e-motor capable of 30,000 rpm. The peak range is over 1,000 km.