Aito is the latest Chinese brand to adopt diecasting. Set up in 2021 by Huawei and Seres it was the first brand under the Harmony Intelligent Mobility Alliance (HIMA) collaboration model where a car producer builds the car but Huawei provides full-stack intelligent vehicle solutions. According to reports at the end of last month, Seres started using diecasting for production of the Aito M9 model and the company claims that this is boosting production capacity.

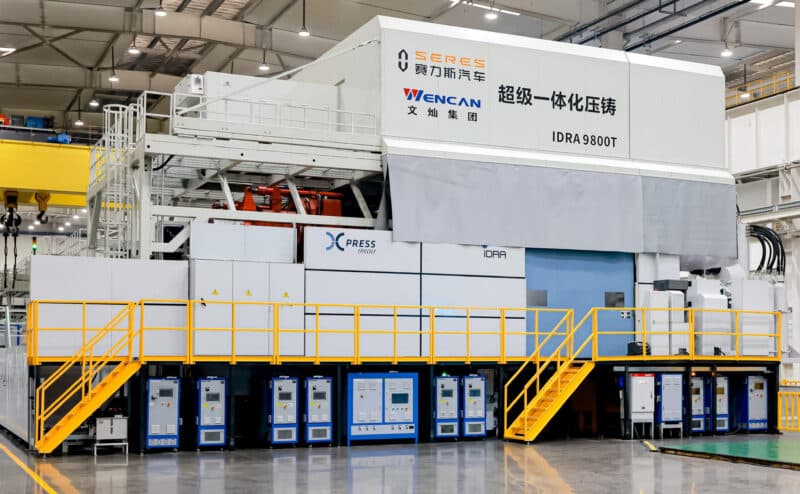

Seres are using a Wencan IDRA9800T unit, which is a 10,000-ton class super diecasting unit. Installation of the unit began in February. The machine is being used to create one-piece diecast rear body units for the Aito M9 (see specs), although not confirmed this is most likely to be for the chassis. What this means is that the number of parts is reduced by nearly 80 and the number of solder joints is reduced by about 1,440. Seres claims it achieves the highest integration of diecasting parts and the torsional rigidity is increased by 23%. Overall it reduces the complexity of manufacturing, greatly improves production efficiency, and effectively improves vehicle endurance and energy-saving efficiency.

The diecasting machine will reportedly be used on the forthcoming Aito M8 as well, the M8 is a five-seat version of the M9. Currently, orders for the Aito M9 stand at over 100,000. Deliveries began earlier this year and so far just over half have been delivered. Seres is hoping that the diecasting machine can help boost monthly deliveries to over 15,000.

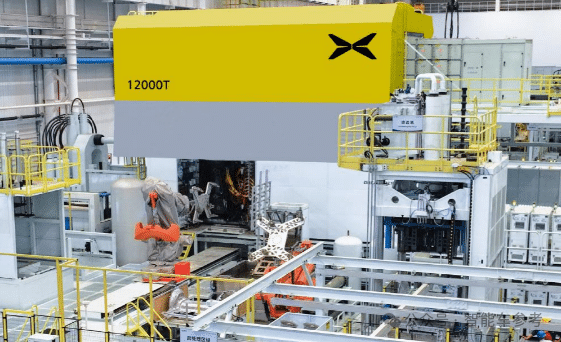

Large-scale diecasting was first used by Tesla, where it is known as the Giga Press. Since then a number of Chinese producers have started such machines to simplify production, reduce costs, and increase rigidity and thereby the safety of cars. Xpeng is currently using a 12,000T machine in the production of the X9 MPV and also uses diecasting for other models. Nio also uses the process, and two months ago we reported about Xiaomi using diecasting to produce the rear floor assembly of the Xiaomi SU7. Xiaomi’s 9100T machine reduces 72 parts that previously required stamping and welding down to just one die-cast part which can be produced in 100 seconds.

Sources: Fast Technology, Fast Technology,