The Big Read – Jiangling (1/3) – Sunny days

Jiangling Motors, often abbreviated to JMC in English literature, holds close relations with Isuzu, Ford, and Renault and its self-developed cars once made headlines all over Europe. Still, it’s one of the lesser-known Chinese state-owned manufacturers. Part of the lower name recognition probably has to do with the fact that Jiangling’s main activities concentrate on vans and light trucks. There are however plenty of passenger cars in Jiangling’s history, branded Landwind, and the company brought forward one of China’s great automotive managers. So, let’s dive in.

The origin story

The history of Jiangling traces back to republican China, where the Jiangxi Provincial Transportation Bureau established the Nanchang Automobile Maintenance Factory in 1947. This repair shop in Nanchang City changed its name to Nanchang Automobile Repair Factory after the communists took power in 1949. In its early years, it was just what the name implied, a repair shop for automobiles.

Like many of its peers, during the Great Leap Forward, the workshop got involved in the national industrialization process. It built small production lines for parts and even explored car assembly. In 1958, the Nanchang factory trial produced two vehicles, a small three-wheeler, and a 2.5-tonne truck. Both were branded Yingxiong, which translates as Hero. The collapse of the Great Leap Forward also ended the car production efforts, the Yingxiong vehicles never reached the production stage.

The factory started making small parts and that instigated another name change in 1962, then becoming the Jiangxi Auto Parts Factory. One of its customers was Nanjing Automobile from Jiangsu province, just north of Jiangxi. It’s probably through this connection that Jiangxi Auto Parts got hold of the drawings of a 1940’s Soviet truck, called GAZ-51. It’s the same design that inspired the Yuejin NJ130, made by Nanjing Automobile, ten years earlier.

Jiangxi Auto Parts started producing its version of the GAZ truck in 1967 while changing the company name to Jiangxi Automobile Manufacturing Plant. The truck was branded Jinggangshan JX130. Jingganshan means Well Ridge Mountains, a mountain range on the border of Jiangxi and Hunan, and the name was also used by Beijing Automobile Works for a small passenger car in the late 1950s.

The Jinggangshan trucks quickly built a reputation for being expensive, high maintenance, and low quality, leaking all kinds of fluids all over the place. Still, Jiangxi Auto added new versions to the original 2,5-tonne truck, like the 2-tonne JX133, the 3-tonne JX131, and the larger 3-tonne JX142. Because of the high price and bad reputation, sales remained low, in the tens per year. Production continued and by 1980 the company had racked up a debt for 56 million yuan. The company was technically insolvent and on the brink of bankruptcy.

Transition managers

If you’re interested in automotive history, you have probably heard of names like Herbert Diess or Lee Iacocca. These were managers that inherited a car company in big trouble and implemented wide-ranging changes to find a way to renewed success. Diess led Volkswagen from the depths of Dieselgate into an electric future. Iacocca saved Chrysler Corporation from going under by inventing the minivan and introducing the K-series cars.

Diess and Iacocca are prime examples of such transitional managers, but they are certainly not the only ones. You could probably name a few more persons who did similar things, but I’m pretty sure you will not come up with the name Sun Min. Yet, Mr. Sun is right up there with Diess and Iacocca, as we will now find out.

Sun Min was born in January 1936 in Hangzhou, Zhejiang province. Little is known about his early life, but Sun graduated from Jilin University in the far North with an automotive engineering degree in 1959. He then started his working with the government’s Eight Machinery Department, responsible for agricultural machinery. Sun mainly developed tractors and in that capacity, he was deployed to the Jiangxi Tractor Factory in 1964, which was a lot closer to his family.

Like many small factories, Jiangxi Tractor was part of a group of loosely connected enterprises, that shared certain services like purchasing or design. In 1980, Sun was appointed the director of the Mechanical Design Institute for the group. It reconnected him with automotive engineering as well, because one of the companies in the group was the Fuzhou Automobile Factory, which will be discussed in more detail later on.

Two years later Sun was selected by the provincial government as a member of a special committee, that should investigate if and how the Jiangxi Automobile Manufacturing Plant could be saved from bankruptcy. After the initial investigation, most committee members concluded Jiangxi Auto was a terminal patient and walked away. Sun Min stayed, had himself appointed as deputy director of the factory, and faced the challenge head-on.

The only way is up

With twenty years of experience in mechanical engineering under his belt, Sun found the first part of his mission to be relatively easy. Fix the quality problems on the Jinggangshan trucks, buy better components, and simplify production. He achieved all those things during the year 1983, cutting the prices of the trucks as well. As a result, sales grew steadily to over 1000 units in 1984, and that year Jiangxi Auto made a profit for the first in its existence. Naturally, Sun was promoted to general manager of the company.

And that was just the start.

While China was moving away from the planned economy, the federal government still held tight control over the car industry through its department called China Automobile Corporation (CAC). This department issued production permits and had a final say over what models could be made. CAC had issued only a small number of production permits, mainly to larger companies. For smaller companies like Jiangxi Auto, it meant ending production or joining a larger company. Jiangxi Auto chose the latter and joined the Nanjing Automobile United Development Joint Venture.

This is the kind of joint venture we saw before with FAW and Dongfeng. The leading company tried to consolidate its entire supply chain and gain more direct control. And of course, these leading companies primarily acted in their own interest. Nanjing Auto wanted Jiangxi Auto to become a spare parts factory and ditch the Jinggangshan trucks. Sun Min disagreed and he fought back. He engaged every contact he had at the provincial party level and in the end he was successful. As long as Jiangxi Auto fulfilled its supply chain obligations to Nanjing Auto, it could also produce its own trucks, using the Nanjing production permit. This was a major victory for Sun.

Yet, he knew the Jinggangshan was an outdated and no longer competitive design, so he desperately needed a new truck. Sun knew exactly what he wanted. In southern China imported Isuzu N-series trucks (of the 3rd generation) were all the rage and he knew CAC had acquired a set of drawings from the Japanese manufacturer. CAC gave these drawings to Beijing Auto Works, who translated them. BAW however build the hugely successful BJ130 truck and had no intention of replacing it with the Isuzu design. So the drawings ended up in a filing cabinet. Sun asked CAC for a copy, but BAW declined to share them.

Again, Sun put the political wheels in motion. His friends in the party pressured CAC and this time he even had Nanjing Auto on his side, as the truck maker was not at all pleased with BAW’s attitude. And again, Sun was successful. CAC offered no objection to him contacting Isuzu directly. In 1984, Sun traveled to Japan and his visit coincided with the launch of the new, 4th generation N-series (basically a facelift of the 3rd generation). Sun saw an opening and asked for an updated set of drawings. Isuzu, which had sold lots of technology to several Chinese companies, saw no objection and even gave them at a low price because they had already sold the drawings before. Sun then persuaded the Japanese into a full technical partnership.

Next, Jiangxi Auto bought a lot of production equipment from Japan and installed a new assembly in the factory. Assembly started in 1986, all from Complete Knocked-Down kits imported from Japan. There was no Chinese content in the beginning, but Jiangxi Auto planned to localize the production slowly. That process took a few years, but around 1989 the only major parts still coming from Japan were the engines and gearboxes.

In a complete reversal of history, the Jiangxi Auto produced Isuzu trucks (they were sold as Isuzu, with full badging from the Japanese company) turned out to be good quality, very reliable, and reasonably priced. The word got out quickly and sales of Isuzu’s exceeded expectations. The launch of the truck came as a complete surprise to BAW, who were not prepared for it. Sales numbers of the BJ130 started dropping, pretty much right away. They dug up their drawings from the filing cabinet and replaced the BAW cab with the Isuzu design. It would take a few years before they also updated the mechanics to the new Isuzu standard.

This spelled the end of the classic BJ130 design and the start of the Isuzu era. BAW now shared the drawings and many smaller and larger truck makers adopted the Isuzu cabs. A practice that continued with later generations of the N-series and still lasts today. The Isuzu cab is the dominant design in the light truck segment. Jiangxi Auto holds one big advantage over its many competitors: it can sport the official Isuzu logos due to its lasting ties with the Japanese company.

Liberation

By the end of the 1980s, CAC finally started to relax its grip on the vehicle market. Instead of the tight control over what vehicles could be made, it introduced the catalog system, More manufacturers had access to a production permit, and models needed to be approved for production, but the manufacturers themselves could choose what to make. In Jiangxi Auto’s case, it meant the company could withdraw from the Nanjing Auto joint venture and go at it alone.

This happened in 1988 and the Nanchang city council, the ultimate controller of Jiangxi Auto, sprung into action right away. It merged Jiangxi Auto with 35 smaller factories and workshops and created the Jiangxi Automobile Industry Group. In the following years, Jiangxi Auto acquired, merged, or reorganized another dozen or so companies, including enterprises like Nanchang Sewing Machine Factory, Jiangxi Trailer Factory, and Nanchang Brake Factory. At the end of this process, Jiangxi Auto Industry was formally incorporated and renamed Jiangling Motors Group Corporation. The date of establishment was July 28, 1991, and Sun Min became the first chairman and general manager of the new company.

By then, Sun had completely changed the fortunes of the company. Remember the crippling debt of RMB 56 million? In 1988 alone, Jiangxi Auto made a profit of RMB 50 million and then another 64 million the next year. This transition had taken a mere six years and was the start of a long, financially stable period for the manufacturer.

The positive financial results also helped with the next point on Sun’s agenda: renewal of the partnership with Isuzu. The initial ten-year contract would soon expire. A year after Sun’s trip to Japan, a delegation from Chongqing did the same. They came home with a joint venture contract, that led to the founding of Qingling Motors. Qingling produced the N-series trucks as well but had quite some success with the TF-series pickup on top of that. Sun wanted to upgrade the Jiangling deal to a joint venture for three reasons: form solid relations, get access to a pickup design and bring engine production to China.

Isuzu wasn’t particularly picky (a few years later it would have three car building joint ventures, two for modified vehicles and about ten in parts production), so Sun’s wishes were granted. In April 19993, Jiangling Isuzu Motors was founded, a joint venture between Jiangling Group (75%), Isuzu Motors (12,5%), and Itochu Corporation (12,5%, a car components trading company from Japan). Jiangling Isuzu would set up its own engine line and produce the TF-series pickup.

The JMC brand

About six months after the joint venture deal with Isuzu, Sun founded a new Jiangling subsidiary called Jiangling Motors Co., Ltd. This is the company we refer to as JMC. Sun had very specific ideas for the company. First of all was to make JMC-branded vehicles and second was starting a JMC engine factory. Although Jiangling was profitable now, both goals did not come cheap, so Sun needed some extra money. Since the political leaders didn’t see the issue and didn’t provide it, he proposed and got an IPO for JMC. In December, the company was listed on the Shenzhen exchange and Sun had the money needed.

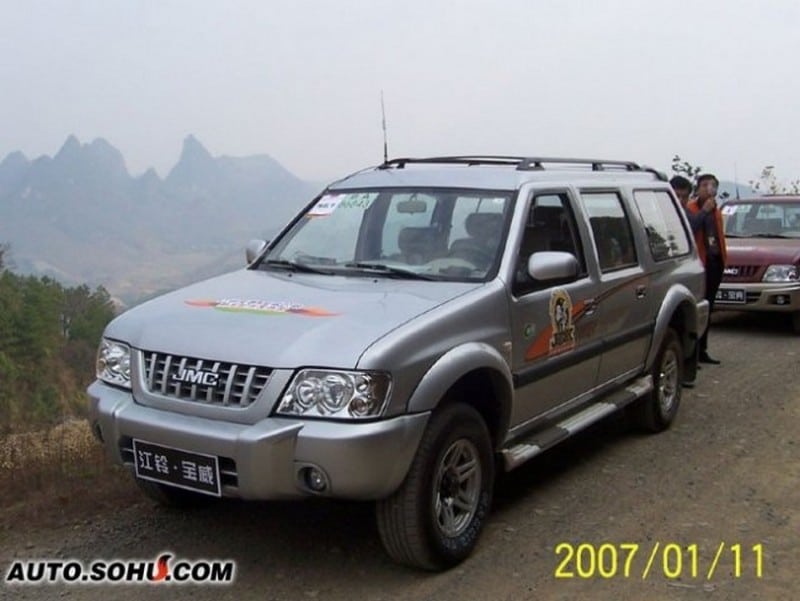

The first JMC cars were the Qingka (Isuzu N-series light truck) and Yunba (Isuzu Midi light van), later followed by the Baodian (TF-series pickup) and Baowei (SUV version of Baodian). The JMC engine plant initially made only the Isuzu 4JB 2.8 liter turbodiesel engine and they put it in everything. In 1995, Jiangling transformed JMC into a joint venture with Ford, but that’s a story for next week.

JMC’s early cars were just rebadged (and sometimes slightly restyled) Isuzu models. But Sun had bigger plans. He saw the market potential for passenger cars and concluded that SUVs and off-roaders had the best market potential. So he turned the company in that direction. Well, not the company, he created another subsidiary in 1999, called Jiangling Lufeng Motors. Lufeng translates as Landwind. This brand will be the subject of the third and final episode of this Jiangling saga.

The Isuzu cars

Now let’s return to Isuzu because we haven’t discussed the cars they make. The N-series truck remains the backbone of the company. Newer generations were introduced in 1994 (5th) and 2007 (6th). The truck is still a best seller and the cab design is a favorite with many other truck makers as well. The 7th generation was launched in Japan recently and will surely find its way to China soon.

More interesting perhaps are the pickups. The TF-series continued until 2014 when it was replaced by the D-Max. Jiangling-Isuzu jumped right to the second generation of the model, the first was neither made by them nor Qingling. The pickup is only available with diesel engines. The original 2.5-liter unit gave way to a larger 3.0-liter in 2017, which was replaced by a 1.9-liter unit in 2019. Some basic versions of this model are still available, but the third-generation D-Max entered the market in 2021, using the same 1.9-liter turbodiesel engine.

Based on the mk. 2 D-Max, Isuzu also offers the mu-X SUV. This is an impressive offroader with five or seven seats. The engine history follows the D-Max, but the mu-X is also available since 2022 with a 2.0-liter turbo petrol. This engine is made by JMC, but it is in fact a relabeled Ford Ecoboost unit. There’s no new generation of the mu-X yet, so it’s still basically the same 2015 car.

Isuzu products are highly regarded for their quality, but they are not cheap. To widen the market appeal of the brand, Isuzu makes two models still based on the D-Max mk. 2 as a more affordable option. The first is the Lingtuo. The model launched in 2018 and still has the original 2.5 TD, albeit upgraded to current emission standards. Last year, the JMC-Ford petrol engine also became available. Contrary to the D-Max, the Lingtuo is also available in a long-wheelbase version.

In 2013 the joint venture agreement was once again up for renewal. On the surface not much changed then, with the cooperation continuing as usual. In reality, there was a major re-structuring of the company. Itochu Corporation withdrew as a partner and the shareholding ratio was equalized to 50% for each of both remaining partners. The company name changed to Jiangxi Isuzu Motors.

With the partners now on equal footing, the other D-Max spin-off was launched under a shared brand. The pickup sold not as Isuzu, but as JIM Ruimai and was powered by the even older 2.8 TD engine. The rather unimaginative acronym JIM simply stands for Jiangxi Isuzu Motors. The Ruimai is the cheapest pickup in Isuzu’s lineup. The ancient engine was replaced by the more modern 2.5 TD unit in 2017, while a 2.0 petrol from Mitsubishi joined the program. With an extensive facelift in 2019, the model name was upgraded to Ruimai S.

Next week

I already told you, but you can expect more about JMC, Ford, and Fuqi pickups.